Environmental Preservation

Environmentally-Friendly Products

Our Notion for Environmentally-Friendly Products

It is the Yokohama Rubber Group’s desire to continue to support co-existence and growth for both people and automobiles through providing tires as our main products. In order to achieve this, we wish to contribute to our customers' happiness and wellbeing by continually providing products that can meet diversified requirements such as not just tires to pursue environmental design, but also tires mainly for sport purposes that can incorporate environmental design whilst aiming to balance environmental design and the drivers' sense of joy for racing.

Furthermore, in our products other than tires, we work to develop environmentally-friendly products that contribute to reductions in greenhouse gas, reductions in chemical substances contained in products, and energy savings.

In terms of newly developed products, our definition of "Environmentally-Friendly Products" is products that exceed 5% or more than existing products on the evaluation average under four categories; "prevention of global warming", "resource recycling", "resource saving", and "safety and comfort" whilst no deterioration is observed from all categories. We aim for all the products to be environmentally-friendly products by 2017.

Four Pillars of Environmental Function and its Index

System Creation so that only Environmentally Products can turn into Commodities

By using "Product Assessment Check Sheet" in new product development, Yokohama Rubber is screening our design adaptability to the environment. The Product Assessment Check Sheet refers to the scores in 17 items in total from planning to production stage of the products, CO2 emissions during usage, ELV compliance in Europe, and so on. Upon conducting judgment of the total score both in initial development stage and prior to mass production, we only go ahead with mass production for products that can meet those standards.

Also, we are deploying our evaluation method called the Environmental Design Radar Chart in order to improve our company's comparison method of our products. This is our method to digitize by comparing with our benchmark (products in 1998) by roughly classifying environmental design into four categories; prevention of “global warming,” “resource recycling,” “resource saving,” and “safety and comfort”. Our evaluation is made more objective by digitizing the degree of improvement by comparing with our existing products.

Currently, we define our Environmentally-Friendly Products as ones that exceed 5% or more than existing products of each index on the average under four categories whilst no deterioration is observed from all categories; we strictly set the rules that any products other than environmentally products will not be approved as new products. By applying this, now, it is no longer easy to develop new products anymore as it has become compulsory even for special sport tires that used to require travelling performance only to clear the preceding criteria as well. We will continue to fulfill our responsibility as a contributing member of the global community as we have our systems in place so that "we will not produce other than environmentally-friendly products". From now on as well, we will contribute to society through our manufacturing by utilizing our various performance simulation technologies and material technologies, not only to reduce rolling resistance, but by thoroughly discussing from the developing concept stage as to which items can meet the standards of environmentally-friendly products in the light of comprehensive aspects.

Radar Chart of our Evaluation for Environmental Function

Ratio of our Environmentally-Friendly Products in the Fiscal Year of 2013

From the fiscal year of 2006 onwards, we started to aggregate the ratio of our environmentally-friendly products versus our entire product line-ups. We are calculating the share ratio versus both in our entire product line-ups and our new products; in the fiscal year of 2013, the share ratio in our entire product line-ups has resulted in 93% which is a 2 point increase compared to the fiscal year of 2012, whereas the share ratio in our new products has achieved 100% from the fiscal year of 2008 onwards.

From now on, we will continue to make various efforts to aim for 100% by the end of the fiscal year of 2017 as to share ratio in our entire product line-ups.

-

Share Ratio of our Environmentally-Friendly Products versus our Entire Product Line-Ups

-

Share Ratio of our Environmentally-Friendly Products versus our New Products

LCA Evaluation for Tires

LCA (Life Cycle Assessment) refers to the method to understand the environmental load (CO2 emission) in numeric data of each stage of the products from production to disposal. For the case of tires, since 80 – 90% of CO2 emission would take place during usage period of their entire life cycle. Yokohama Rubber is especially focusing on "coming up with environmentally-friendly products to realize low fuel consumption".

Yokohama Rubber's Manufacturing Philosophy Imputed in "BluEarth"

Yokohama Rubber has been pursuing technology and product development by focusing on the improvement of fuel consumption by reducing rolling resistance, along with our major launch of "eco tire DNA" since 1998 well ahead of our competitors. However, pursuing fuel efficiency and environmental friendliness would not suffice to fulfill our responsibility as a tire manufacturer.

In order to win even better customer satisfaction, not just "fun" and "joy" that can contribute to motorization per se, we needed to realize product development of the next stage under a new concept of being "gentle to people and society".

As a result of new technology and product development promoted for the purpose of achieving these performances, we released BluEarth in 2010.

Starting with BluEarth-1 EF20 that has received the highest AAA/a grading, our product lineup also includes BluEarth-A that has a top WET grading, BluEarth AE-01F that has the highest grading for low fuel consumption, and BluEarth RV-0 fuel-efficient tires for minivans.

In terms of products for commercial vehicles, we have launched the BluEarth LT152R fuel-efficient rib tire for small trucks and buses. We offer a broad lineup of fuel-efficient tire, for uses ranging from passenger vehicles to consumer vehicles.

Furthermore, we have also incorporated the new technologies fostered with BluEarth in other tires and attached “the BluEarth Technology Mark” to designate the tires that are equipped with these technologies.

*New technologies that constitute “BluEarth Technology”

- Technology to maintain fuel efficiency and less hassle for maintenance work called "AIRTEX" – our endeavour to achieve "zero" air leak

- Natural material and material technology to reduce WET stress called "Orange Oil"

- Evaluation technology to digitize the relativity between human muscle force and stress called "Biological Monitoring"

- Technology for relativity detection between aerodynamics of the tires and travel resistance

BluEarth Technology Mark

|

Technical Development aimed at a Sustainable Society

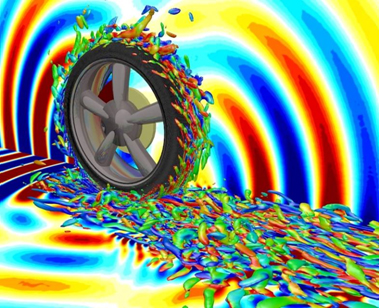

Tire tread hydraulic noise simulation

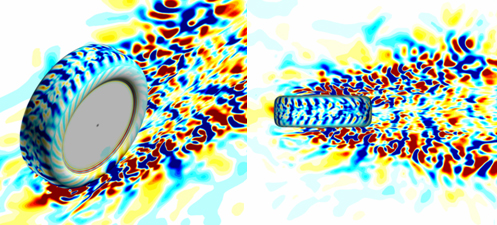

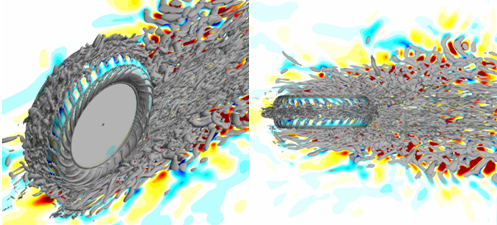

Yokohama Rubber conducts R&D on reducing vehicle air resistance for insider fin tires, etc. This research grew from the idea that it might be possible to reduce air resistance for an entire vehicle by changing the flow of air surrounding a vehicle through the shape of tire when discussing the results of a simulation of the flow of air surrounding vehicles. If it is possible to use simulations to visualize phenomenon that were unseen up until now, this can bring different ideas to light, and allow us to arrive at innovative technologies as a result. This is one of the major roles that we expect of simulations. However, because there are many complex phenomenon that cannot be simulated, in many cases it is necessary to improve the computing power of supercomputers and to improve simulation technologies.

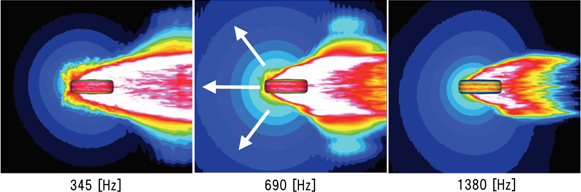

Reducing vehicle noise is an issue that concerns both reducing fuel consumption and contributing to environmental preservation. Tire-related noise can be broadly divided into direct sound from air transmission and indirect sound from solid transmission. It is particularly difficult to experimentally visualize the phenomenon of direct aerodynamic noise caused by tires, and for this reason visualization through simulation was called for. However, there were major challenges for high-precision hydraulic noise simulation of tires that rotate on the ground concerning both the computing power of supercomputers and simulations technologies that were described above. In response, we addresses these challenges with the cooperation of the research groups of Professor Takashi Fuji (JAXA (Japan Aerospace Exploration Agency (JAXA) / ISAS (Institute of Space and Astronautical Science)), who is particularly well-renowned for hydraulic noise simulation in the field of space development.

While there were limitations in calculation accuracy for the area tires came in contact with the road surface using past simulation technologies, Takashi Fuji (JAXA/ISAS) succeeded in improving the calculation accuracy using a high resolution calculation method fostered through space development. Furthermore, by directly simulating a detailed tire model utilizing the super computers of JAXA and the Tohoku University Cyber Science Center, we succeeded in simultaneously calculating the flow of air around a rotating tire tread and the acoustic field at nearly actual scale. As a result, we were the first in the world to demonstrate that in addition to the noise generated by the turbulent flow of air around tire treads, noise is also generated by the compression of air in front of tires caused by tire rotation.

We succeeded in gaining a precise understanding of the vortex structure and acoustic waves caused by running tire treads, an understanding that was not possible to have up until now. We plan to continue research going forward in hopes of achieving innovative technologies that can contribute to reductions in pass-by noise and improvements in aerodynamic performance.

Figure 1: Tire tread pressure distribution (oblique view, view from above)

Figure 2: Tire tread vortex flow structure (oblique view, view from above)

Figure 3: Tire tread sound pressure level distribution (oblique view, view from above)

Figure 4: Tire tread air vortex flow structure and acoustic waves (1,380Hz mode 1)

Tire-related environmentally-friendly products

27.00R49 RB42 radial tires for large construction vehicles

In the global large OR tire market, because tire heat dissipation is higher in locations requiring long-distance transport, especially in the case of mines that take on an even larger scale, demand has increased for radial tires that have higher insulation resistance than bias tires. Radial tires now account for approximately 90% of tires in these situations. We have developed large OR tires with 49-inch radial tires as the main size, and launched the new pattern RB42 in May 2013.

One of the features of the RB42 is that it uses a non-directional block pattern and has deep grooves that fall into the E4 category of the TRA code. These tires provide excellent driving force in areas with gravel and mud that are characteristic of mining areas. These RB42 tires can withstand harsh usage environments as the strengths of radial tires have been leveraged to achieve an improvement in insulation resistance compared to conventional bias tires (Y523) and durability has been improved by optimizing the placement of materials in the belt and bead portions within the tire structure. Furthermore, anti-wear performance has been improved by increasing the strength of treads through the adoption of a radial structure, which leads to longer lasting tires and a reduction in resources used as a result.

In addition to the RB42 size, 24.00R35 and 18.00R33 are also available, supporting the needs of dump trucks in the 40 to 100 ton class.

-

RB42 tires for large construction vehicles

-

100-ton class large dump trucks

LT151R high wear performance rib tires for trucks and buses

LT151R is a new product that aimed to achieve a complete overhaul over the previous PROFORCE RY01 product in terms of aspects including the tread compound, tread pattern, profile, and structure in order to provide the long life demanded by commercial vehicle users.

In order to achieve long life, we newly developed a dedicated tread compound employing Yokohama Rubber’s own Synchro Carbon that consists of fine-grained carbon with differing grain size blended at the optimal volume ratio. The tread pattern was newly designed, taking the five-rib structure of PROFORCE RY01 and using a pattern with four high-rigidity ribs with an expanded rib width. In doing so, wear performance has been improved by 28% compared to PROFORCE RY01, and both operation stability and wet performance have been achieved. Furthermore, the distortion reduction profile design technology fostered in the development of ZEN large truck tires was employed, and the casing durability has been greatly improved as a result.

As a result of the above, LT151R tires give consideration to safety and comfort while contributing to a reduction in resources used based on their long life.

Figure 1. Photo of the tires

Figure 2. Product logo

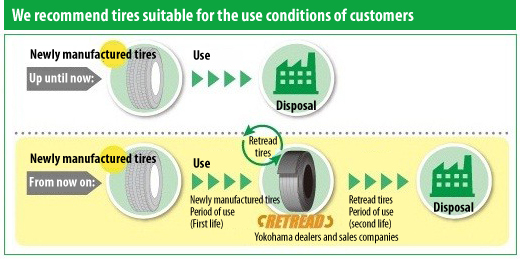

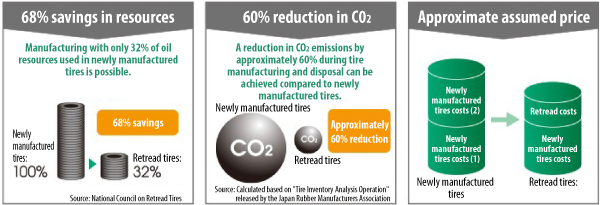

Retread tires

Retread tires are re-used tires in which a buff machine (a planning machine) is used to uniformly cut the tread surface of a tire that has been worn away through driving, after which new tread rubber is affixed and vulcanized to restore the function of the used tire. They are also called retreaded tires.

The reuse of resources reduces the number of waste tires and contributes to the reduction of CO2 emissions that would otherwise be released in the tire production process. Demand for retread tires has increased in recent years because they are economical due to reduced costs.

In addition to our existing products, the product lineup for retread tires includes products based on the Z.ENVIRONMENT concept of ultimate comprehensive environmental performance under the new tire brand of ZEN for trucks and buses. The products that have been released under this brand include ZEN 701ZE, which is a premium all-season tire that focuses on abrasion resistance; ZEN 702ZE-i, which is a premium all-season tire that focuses on fuel efficiency; ZEN 902ZE, which is a studless tire that focuses on fuel efficiency; and ZEN 903ZW, which is a studless tire that focuses on performance on snowy and icy surfaces.

About retread tires

Retread tire manufacturing method

Benefits of retread tires

The ZEN retread tires lineup

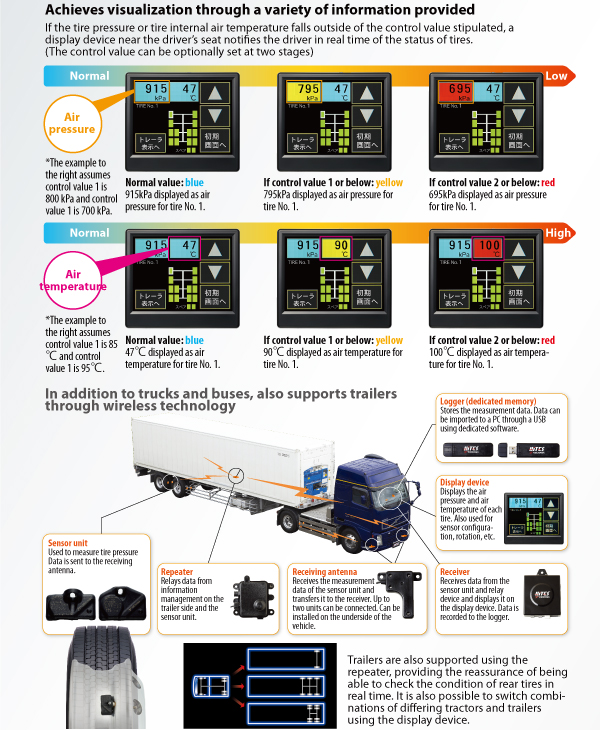

The HiTES monitoring system for truck and bus tire pressure

The HiTES system that provides information on tire pressure and temperature in real time has been renewed. Visibility and operability have been significantly improved through adoption of a 3.5-inch LCD touch panel, and in addition to existing JIS and ISO-standard rims, it also supports new ISO-standard rims for new large trucks.

In addition, the operation steps during tire rotation and trailer switching work have been greatly simplified.

In addition to serving as a safety measure through the early detection of flat tires and abnormal break heating, HiTES also controls deterioration in fuel economy and improves tire life through appropriate air pressure management and contributes to environmental preservation measures such as reductions in CO2 emissions and resources used through means such as the use of retread tires.

Click here for the official HiTES site.

The various display functions of HiTES that provide notices on the status of tires in real time

MB Group environmentally-friendly products that are applicable to a wide range of industrial fields such as land, ocean, and air

70 MPa resin hose for hydrogen stations

A hydrogen replenishment hose has been developed for use at 70 MPa hydrogen stations to serve as part of the infrastructure to promote the expansion of fuel cell vehicles that are expected to be the ultimate in eco-cars that do not emit air pollutants or CO2 while driving. Through verification* at 70 MPa hydrogen stations we have improved safety and workability during vehicle replenishment.

*The commissioned project of New Energy and Industrial Technology Development Organization (NEDO)

A highly flexible and durable high-pressure large-diameter hose for large-scale construction machinery

The operating parts of construction machinery (power shovels, dumpers, etc.) are hydraulic, and hydraulic hoses serve the role of conveying that pressure. Among the many types of construction machinery, hoses used in machinery for excavating mine resources must not only be large and capable of high output, but because they are used in harsh environments, hydraulic hoses require high performance in all aspects, including supporting high-pressure, having large diameters, and being flexible. In the design of the high-pressure large-diameter hoses for mining construction machinery that we have recently developed, we have achieved better flexibility and higher durability than existing products through FEM analysis of hose movements using actual machinery and the optimization of construction and materials. In doing so we have reduced the frequency of hose replacement and contributed to reductions in waste materials.

Development of the general purpose Duotex conveyor belt that achieves both a long life and the ability to recycle

The Duotex series consists of general purpose conveyor belts optimal for carrying various loose items such as crushed stone, cement, wood chips, and lime. The series is mainly for use at locations such as stone pits, recycling yards, and fresh concrete plants in Japan (Figure 1).

With the recent renewal of the series, we newly developed highly-abrasion resistant rubber for the cover rubber in the Duotex series, a part which has a significant impact on the life of products. In addition to improving the basic function as a belt, reduced weight and composition with recycled materials is also achieved, making it an environmentally-friendly product that achieves a balance between having a long life and allowing for recycling.

By using newly developed rubber, the usage of reclaimed rubber has been increased by approximately 20 tons per month. The results of the Group’s contributions to resource recycling have been recognized through the receipt of an encouragement award from the Japan Environmental Management Association called the FY2013 Resource Recycling Technology and System Award in October 2013.

In terms of the belt structure, all of the core belt material is two-ply (two-layered), with the endless portion being more stable than existing products. In addition, by using the extremely flexible characteristics of the two-ply structure, it has become possible to make the pulley diameter smaller than in existing conveyor systems and an efforts was made to achieve more compact equipment design. The extensibility of the belt has been well received and the same level of low extensibility has been achieved as existing products (Figure 2).

-

Figure 1: The Duotex conveyor belt

-

Figure 2: Duotex catalog

Highly durable and reliable marine hose that supports new international standards

The marine hose that we have developed under the Seaflex brand has been developed as a marine hose that supports the new GMPHOM2009 standards established by the Oil Companies International Marine Forum (OCIMF) and formal certification has been acquired for all models (Figures 1 and 2).

The GMPHOM2009 standards that have been revised for the first time in 20 years have stipulations that cover the manufacturing, specifications, and testing methods of marine hoses. The standards call for higher durability than in the past and have introduced a large number of strict conditions such as dynamic fatigue tests that take place up to 25,000 times.

Marine hoses are large hoses used in the marine transport of petroleum and crude oil, and are used for equipment such as systems carrying crude oil between tankers moored to buoys on the sea and equipment used in the production, storage, and shipment of floating petroleum and gas used in undersea oil field development. Because there is the risk of serious marine pollution incidents occurring if these hoses become damaged, they are required to be highly reliable against things such as oil leaks.

Figure 1: Prototype testing dynamic torsion and bending status (formal certification test)

-

Figure 2: Prototype breaking test (formal certification test)

-

Figure 3: New standards prototype use status

Development of VS-1 high surface-pressure compact rubber bearings for bridges

Rubber bearings for bridges are installed between bridge girders and bridge piers and fulfill the role of supporting the load of bridge girders and absorbing and seismically isolating the flexion, expansion, and contraction of bridge girders. The VS-1 high surface-pressure compact rubber bearings that have been developed employ a unique design using cylindrical steel (pot plate) to surround like a wall a laminated rubber circle composed of stacked up rubber and steel plate (Figure 1). In doing so the unique tractability of rubber bearing is maintained while being able to support high pressure of approximately twice (25N/mm²) that of conventional products, achieving high-level load support performance. In addition, because the pot plate restricts excessive transformations, this means that there is little distortion in the rubber even under high pressure and the load on internal steel plates is reduced. Accordingly, the steel plates are thin, making possible a product that is much smaller and lighter compared to existing products(Figure 2)

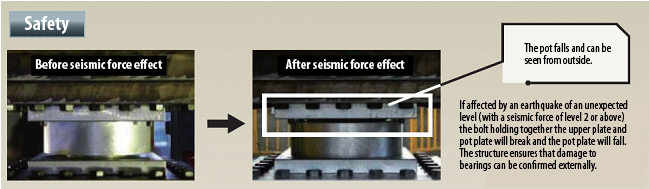

Furthermore, even if a load higher than the allowed range is applied such as in a large earthquake, the structure is such that first the bolt holding together the upper plate and pot plate will break and a gap will open between the pot plate and fixture materials. Through this mechanism it is easy to see the parts requiring maintenance from outside, improving safety and workability (Figure 3).

Utilizing these characteristics, it is possible to use the product in bridges that have become dilapidated or damaged in addition to newly built bridges, and accordingly it is hoped that the product can contribute to bridges with longer lives and resource savings.

-

Figure 1: VS-1 structure and characteristics

-

Figure 2: Size comparison

Figure 3: Damage visibility feature

The Medi-Air wheelchair cushion

So that wheelchair users can feel reassured sitting in their wheelchairs, Yokohama Rubber has developed the Medi-Air series of wheelchair air-cell cushions. Yokohama Rubber has provided a series of products using rubber and air for the purpose of shock absorption, including tires that absorb the shock between cars and the road, air fenders that absorb shocks to enable tankers to be moored to quays, and air springs for industry. We hope that the development of these technologies can serve in some small way to improve “the quality of life” for wheelchair users by making sitting less painful and mitigating the risk of bedsores.

As a new product in “the Medi-Air” series of wheelchair air-cell cushions, “the Medi-Air Sky (Figure 2)” was released in May 2012 to accompany the existing “Medi-Air 1 (Figure 1)” product. This new product was then awarded with the 2012 Good Design Award in October.

“The Medi-Air Sky” uses a structure that allows for air adjustment to be conducted manually and was developed based on the theme of a product that allows wheelchair users that are able to propel themselves to enjoy going out “more readily and more freely”. Through a function that detects and notifies with a sound before hitting the bottom, we have aimed to expand the range that wheelchair users can feel reassured to operate in. “Medi-Air Sky” is also a product for which welfare equipment rental is covered by nursing-care insurance, and under the Services and Supports for Persons with Disabilities Act costs are provided for as a supportive device.

Medi-Air series employs the unique air isolation technologies and sensor technologies of Yokohama Rubber to achieve features that have not been provided with air cushions up until now, such as “the simple replacement of air cells (Figure 3)” and “a sensor for detection before hitting the bottom (Figure 4)”.

-

Figure 1: Medi-Air1

-

Figure 2: Medi-AirSky (winner of the 2012 Good Design Award)

-

Figure 3: Air cell removed

-

Figure 4: Sensor for detection before hitting the bottom

Aircraft lavatory module using recyclable thermoplastic plastic

While fiber-reinforced plastic (FRPs) parts that are used in large quantities in aircraft are light and high strength, because they are materials that are difficult to recycle, they are generally disposed of by burning or pulverization.

The lavatory module for the Boeing 737 aircraft that has been recently developed uses flame-resistant PVC recyclable plastic chips to replace the glass-fiber reinforced plastic (GFRP) used in large quantities in interior parts. By forming the product with an optimal wall thickness the mass, strength, durability, airworthiness, and flammability characteristics of previous products is maintained while a contribution is made to reductions in the environmental footprint through the adoption of recyclable materials.